Skoolie Walls!

$500 down and a week of waiting proved worthwhile in the long run, as I now have walls!

The local welding supply shop sold steel at roughly $50 a sheet at 8' x 4' x 14ga hot roll steel. They used a forklift and I dragged each 100lb sheet into the bus through the back door. I was fortunately prepared for this and brought a buddy along.

I had to immediately get primer on it (after cleaning any residual machining oils off) because as it is not galvanized, rusting would have started immediately. Orienting and re-orienting the sheets of steel was an adventure, especially with 15-20kt winds, but I managed to get them somewhat behind the house which blocked a great deal of the wind. (see https://youtu.be/7OO3l6l4CgE for the time lapse and ceiling discussion) After letting them dry, I called a welder recommended by the welding supply company and he came out to cut the sheets of steel by 10" so that they fit when attached.

Initially, I was thinking I'd hoist the sheets into position and then mark the holes I'd drill and then realign the sheets. The welder believed that if I could get a friend to come out and hold the sheets, he could spot weld them onto the bus enough that they would hold while I drilled through them. This is so much easier than my plan. For less than $80 I have saved countless hours, a great deal of effort and much headache.

I will cut window holes as I acquire windows, which are EXPENSIVE if you're buying RV specific double paned windows. Also, concerning the doors, I'm trying to find a way to have them welded from the top to extend them towards the 10" raised ceiling. Having a mostly watertight bus means that I can start working on the wood sub-floor over the Holiday break!

The rivets that I'll be using are steel, blind, pop rivets on the exterior that each have a shearing strength of 1,100lbs. I'd recommend getting a rivet gun for anyone who's never riveted before... Also, with 900 potential rivets to complete, I'd develop quite the hand cramp if I didn't buy one.

My project as of now is to drill holes through the support ribs. 12ga steel and a 14ga make nearly 1/4in and it takes all of my weight to drill through. Additionally, in order to prevent the destruction/warping/breaking of my drill bits, I'm going suuuuuuper slow, which has worked well... but now each post takes about 35-40 minutes for each post (30 or so holes). 26 total posts on the bus. It's gonna take some time. I'll post the other projects I've been working on in the meantime.

The local welding supply shop sold steel at roughly $50 a sheet at 8' x 4' x 14ga hot roll steel. They used a forklift and I dragged each 100lb sheet into the bus through the back door. I was fortunately prepared for this and brought a buddy along.

|

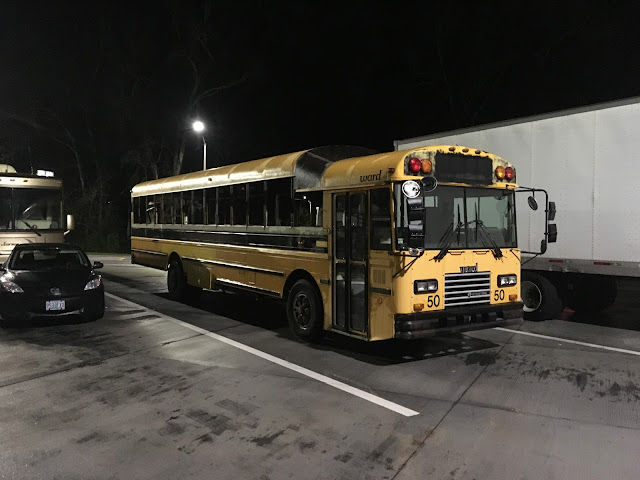

| Just prior to washing. |

Initially, I was thinking I'd hoist the sheets into position and then mark the holes I'd drill and then realign the sheets. The welder believed that if I could get a friend to come out and hold the sheets, he could spot weld them onto the bus enough that they would hold while I drilled through them. This is so much easier than my plan. For less than $80 I have saved countless hours, a great deal of effort and much headache.

I will cut window holes as I acquire windows, which are EXPENSIVE if you're buying RV specific double paned windows. Also, concerning the doors, I'm trying to find a way to have them welded from the top to extend them towards the 10" raised ceiling. Having a mostly watertight bus means that I can start working on the wood sub-floor over the Holiday break!

The rivets that I'll be using are steel, blind, pop rivets on the exterior that each have a shearing strength of 1,100lbs. I'd recommend getting a rivet gun for anyone who's never riveted before... Also, with 900 potential rivets to complete, I'd develop quite the hand cramp if I didn't buy one.

My project as of now is to drill holes through the support ribs. 12ga steel and a 14ga make nearly 1/4in and it takes all of my weight to drill through. Additionally, in order to prevent the destruction/warping/breaking of my drill bits, I'm going suuuuuuper slow, which has worked well... but now each post takes about 35-40 minutes for each post (30 or so holes). 26 total posts on the bus. It's gonna take some time. I'll post the other projects I've been working on in the meantime.

Comments

Post a Comment