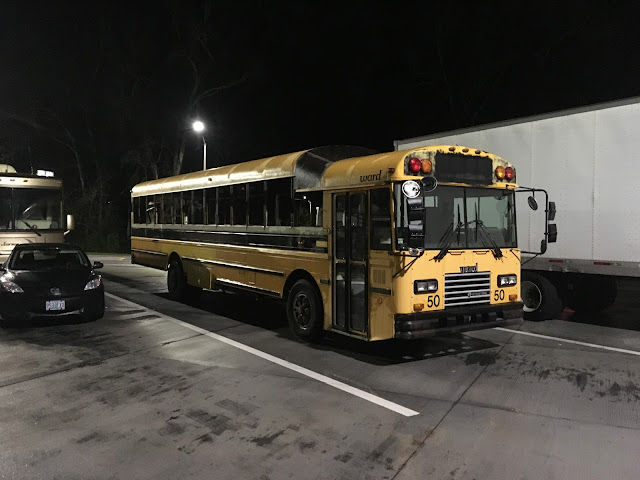

Ward, like many other bus manufacturers didn't really care too much about the coach compartment interior. The floors are usually covered in plywood with a rubber mat on top. None of the holes through the floor are ever sealed and if rust happens, the school district will simply sell the bus anyway. These machines are built to last (due to federal regulations for hauling kids around), but they take shortcuts wherever they can along the way. I want this to be a dependable house for me and the next (possible) owner.

|

| Ward is well known for making amazing engines and chassis but NOT for their coachwork. |

|

| The offending bolt holes. |

|

| More bolt holes. |

|

| The solution. |

For the smaller holes I decided to use roof flashing caulk. It is a very rubbery, yet permanent solution that is waterproof, heat resistant, vibration resistant, and still flexible. Of course that wouldn't work for the larger holes that I encountered. The caulk would simply drip through the hole due to the size. I got a sh*tload of dimes (119 to be exact) and a Loctite Epoxy set and went to work. It wasn't that hard, but it did delay my painting by a day as I wanted to make sure that the coins had a full day to cure in place.

|

| The cheap, quick, and permanent solution. |

I also used this opportunity to grind down the remaining screws that jut from the floor, as they had previously been broken in the removal process.

Finally, I ordered 9 pieces of sheet metal (8'x4'x16ga) at $51 a panel. Before I attach them to the bus exterior I'm going to have to prime them because it is NOT galvanized steel and will rust if exposed to rain or moisture for any amount of time.

***Fast Forward***

I got the final coat of Rustoleum Hard Coat Enamel down on the floor. It looks great and I got it down 24 hours before the rain hit! Of course after the rain came, the temperature dropped to freezing. Yes. In Del Rio, Texas, we saw snow.

|

| Rustoleum enamel top coat. Green wasn't any more expensive, so why not?! |

Comments

Post a Comment